-

New Zealand

Mechanical Design Services

Mechanical Design Services

Techniqy Team is focused on offering end-to-end mechanical design services across the product development lifecycle. Our exceptional team seamlessly navigates the entire spectrum, from conceptual mechanical engineering design to production. Our product development process ensures swift design, reduced cycle times, and enhanced return on investment (ROI).

Overall, the impact of implementing these design strategies is a more streamlined, cost-effective, and responsive design process, leading to enhanced competitiveness and successful product outcomes.

Mechanical design services involve the creation, development, and optimization of mechanical systems, products, or components. These services are typically offered by engineering firms, freelance engineers, or in-house design teams and can include various stages of the design process from conceptualization to prototyping, testing, and final production.

Key Offerings of Mechanical Design Services:

- Conceptual Design:

- Initial ideation and brainstorming to generate design concepts.

- Feasibility studies and preliminary sketches or CAD models.

- 3D Modeling & CAD Design:

- Creation of detailed 3D models using CAD software (e.g., SolidWorks, AutoCAD, CATIA).

- Assembly modeling and part design.

- Prototyping:

- Development of physical prototypes using techniques like 3D printing, CNC machining, or other fabrication methods.

- Virtual prototyping and simulation for cost-effective testing.

- Engineering Analysis & Simulation:

- Finite Element Analysis (FEA) to assess stress, strain, and fatigue.

- Computational Fluid Dynamics (CFD) for fluid flow and heat transfer analysis.

- Kinematic analysis for moving parts or mechanisms.

- Product Optimization:

- Design for manufacturability (DFM) to simplify production.

- Material selection for strength, weight, and cost considerations.

- Weight optimization for improved performance and efficiency.

- Detailed Engineering Drawings:

- Generation of 2D drawings with tolerances, dimensions, and manufacturing notes.

- BOM (Bill of Materials) creation for component sourcing.

- Reverse Engineering:

- Analyzing existing products to improve upon them or replicate design features.

- 3D scanning and re-design based on old or obsolete components.

- Manufacturing Support:

- Collaboration with manufacturers to ensure smooth production.

- Design adjustments based on feedback from the manufacturing process.

- Testing & Validation:

- Physical testing of prototypes to ensure performance and durability.

- Compliance with industry standards and safety regulations.

Industries Benefiting from Mechanical Design Services:

- Automotive: Design of vehicle components, engine parts, and interior systems.

- Aerospace: Development of aircraft systems and structures.

- Consumer Products: Design of everyday items such as appliances, electronics, and tools.

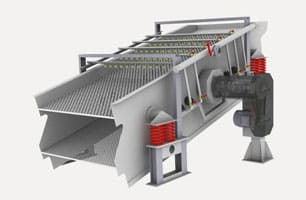

- Industrial Equipment: Design of machinery and equipment for manufacturing or processing.

- Medical Devices: Precision engineering for tools, instruments, and devices in healthcare.

Would you like to know more about specific services or have a particular project in mind?

Our Mechanical Design Services encompass a broad spectrum of expertise include:

Concept Designing

Jigs and Fixtures Designing

Tool Design

Sheet Metal design

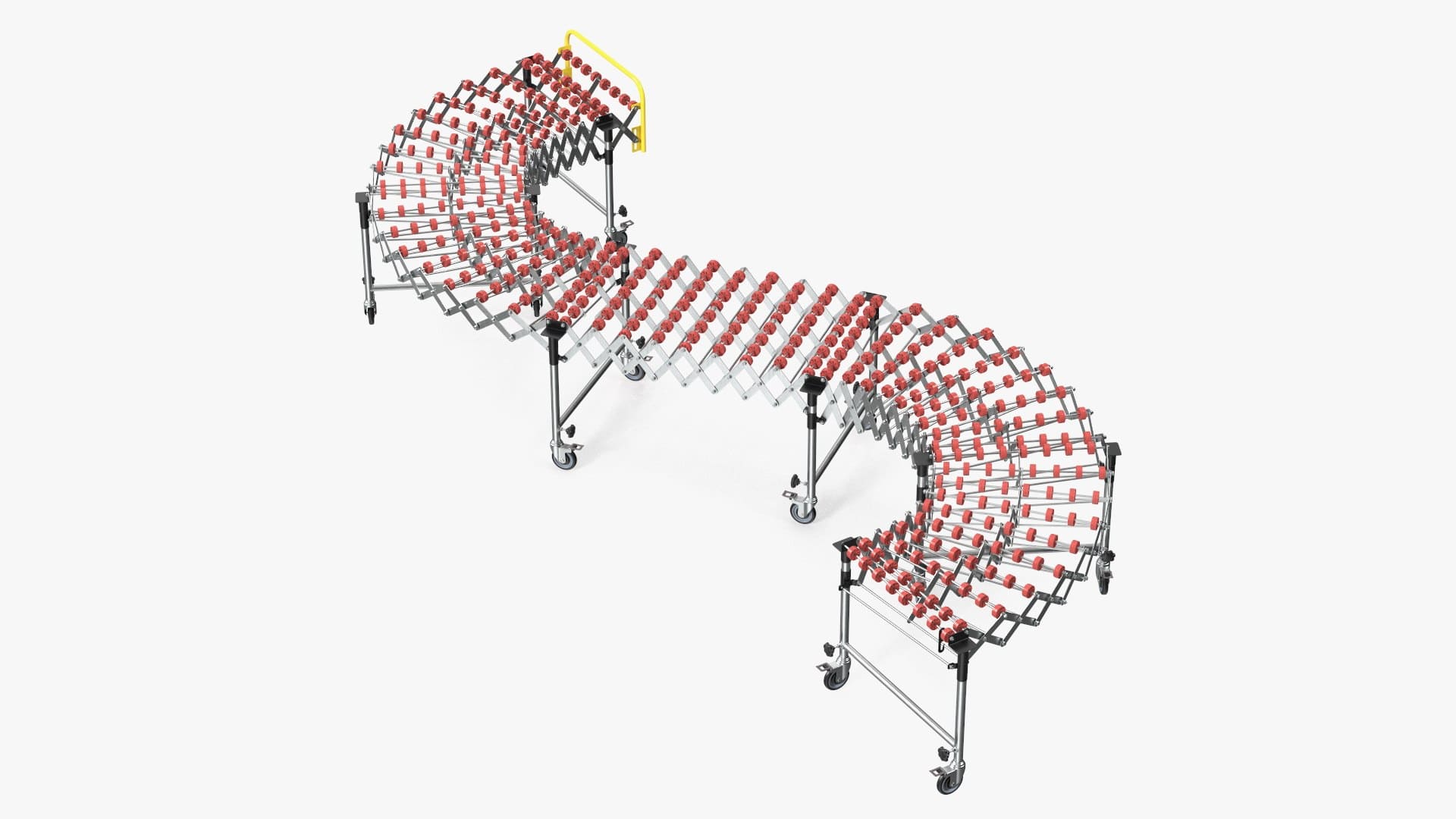

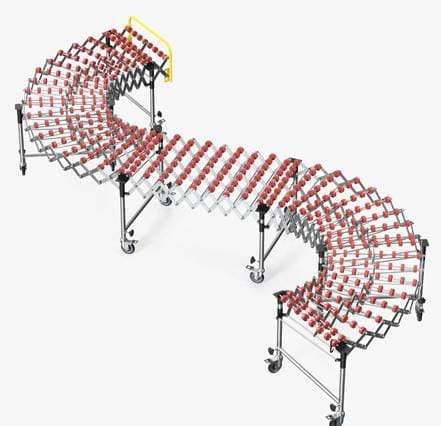

Material Handling Equipment Design

Value Analysis / Value Engineering

Food Processing Equipment Design

Pressure Vessels and Tanks Design

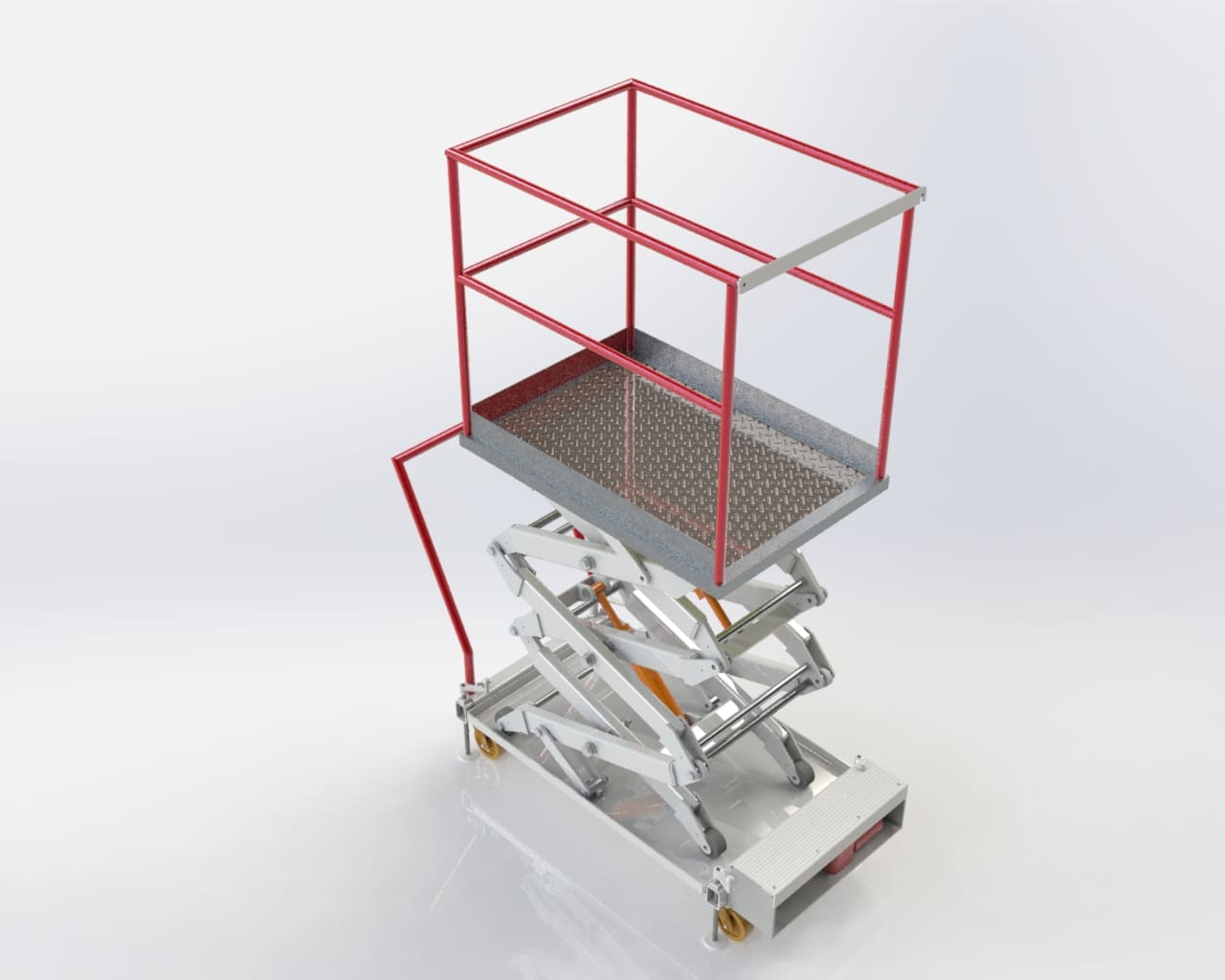

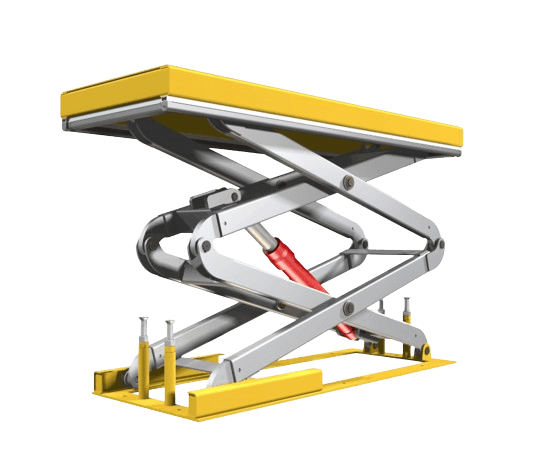

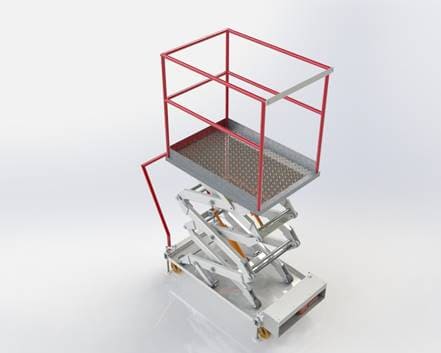

Lifting Equipment Design

Air Pollution Control Equipment

Storage Silos and Bins Design

Air Handling Equipment Design

- Designing for Manufacturing (DFM)

- Flexible Modelling Approach

- Parametrically Controlling of Design

- Design Reusability

- Value Analysis / Value Engineering

Design strategies:

Overall, the impact of implementing these design strategies is a more streamlined, cost-effective, and responsive design process, leading to enhanced competitiveness and successful product outcomes.

CAD Competency

- SolidWorks

- Autodesk AutoCAD

- Autodesk Inventor

- PTC Creo

- NX UG

- Fusion 360

Industries We Serve

Lift Truck

Pneumatic Conveying System

Scissor Lift

Conveyors

Molding Products

Casting Products

Sheet Metal Products

Machining Parts=

Pressure Vessels

Tanks

Silos

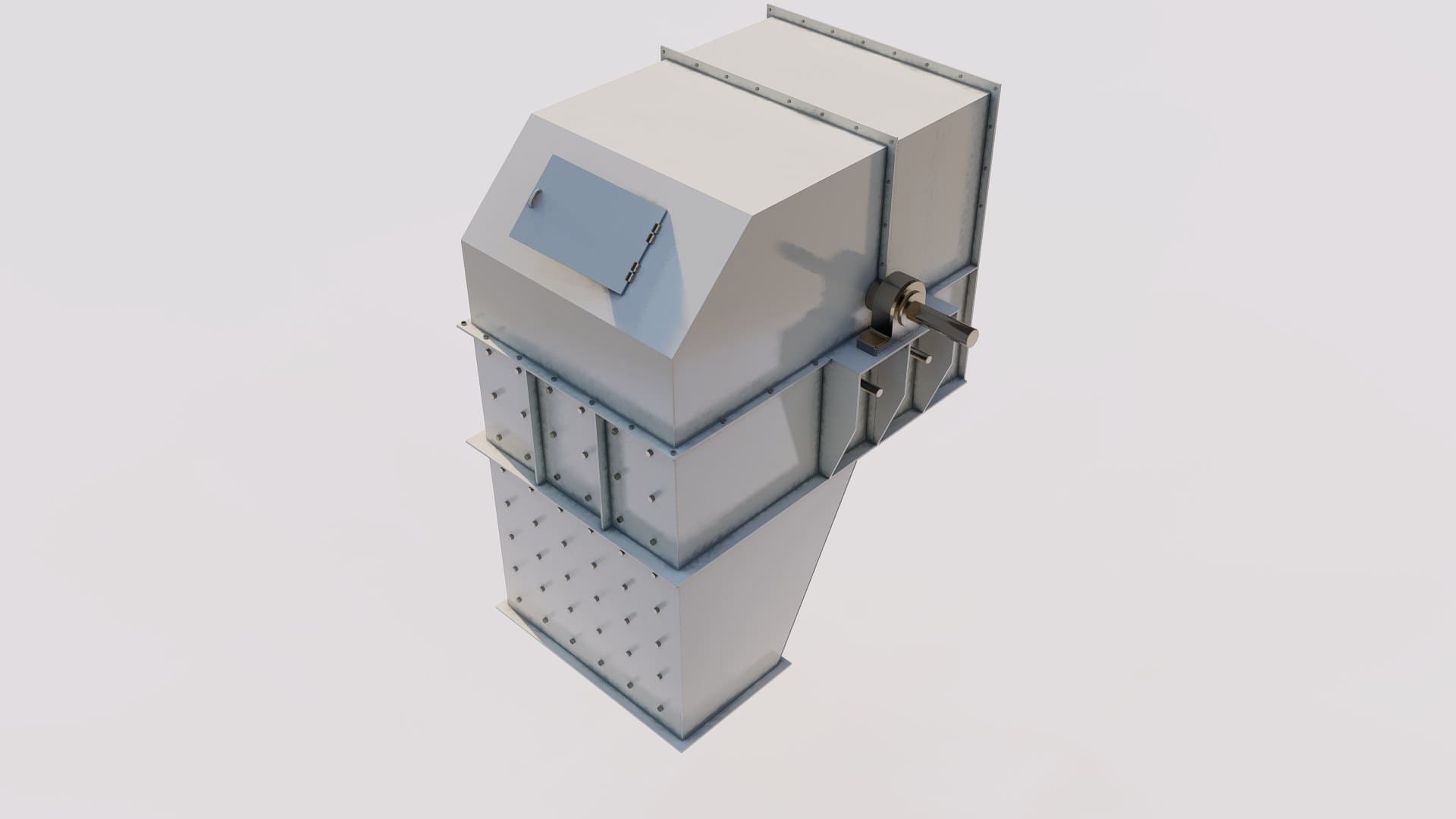

Chutes

Air Filtration Equipment

Air Pollution Equipment

Scrubbers

Hopper

Sterilizers

Soak/Flotation Tanks

Spray Washers

Rotary Valves